Zf Repair Manual Download 5hp24

ZF 5HP24 Transmission Repair Manual PDF free online

This manual covers the procedure for repairing the complete transmission. The repairing of this transmission is only allowed to persons with an specific training from ZF Getriebe GmbH.

ZF 5HP24 Transmission Repair Manual. Picture of the transmission, Diagram of power flow, Tightening torques, Transmission test, Special tools, Function tests, Disassembly, Assembly, Transmission with selector mechanism and parking lock, Brake F with freewheel, 1st gear, Oil supply. This workshop repair manual was issued by ZF company for use by dealers and mechanics from repair centers. Manual for ZF 5HP24A, ZF 5HP24 provides user with precise information about repair and service of automatic transmissions ZF, power take-offs, retarders, suspensions for passenger cars and trucks and other production of the company. Zf 5hp24 auto transmission workshop service repair manual parts catalog manual also included transmission covered: 5-speed automatic transmissio. Download 14.95 USD. Zf5hp24 Repair Manual This workshop repair manual was issued by ZF company for use by dealers and mechanics from repair centers. Manual for ZF 5HP24A, ZF 5HP24 provides user. Transmissionpartsus.com offers ZF ZF5HP24 transmission parts. 139400A ZF repair manual, ZF5HP24 RWD ONLY ZF manual. ALT VENDOR # 185400B. ZF 5HP24 Automatic Transmission - Spare Parts Catalog. ZF 5HP24 Automatic Transmission - Spare Parts Catalog 5HP24 Technical Information Torque, Gear Ratio & Weight Input Torque 1st. English 5HP24REP 5HP24 Repair Manual All Eng/Ger 1058 764 001 5HP24 Wall Chart All. Jun 11, 2019 ZF 4HP22 6HP26 5HP19 5HP24 5HP30 TRANSMISSION GEARBOX FACTORY WORKSHOP SERVICE REPAIR MANUAL (pdf version) This is a comprehensive factory manual service manual for ZF TRANSMISSIONS. This manual has been written in a format that is designed to meet the needs of technicians worldwide.

The entire disassembly and assembly procedure is described in chronological order.

The photographs were kept general in nature so that they can be used with various applications; they are not binding in every case.

We use Service Bulletines and training to announce important information and application-specific changes that must be taken into consideration in maintenance work.

Honeywell st 3000 smart pressure transmitter manual. If this repair manual is given to a third party, there will be no modification service.

The Service Bulletines regulations and specifications must be followed when making repairs. Depending on the type of damage that has occured, the repair work can be limited to that which is necessary to repair the damage.

Here, you must observe the following:

- Seals (such as O-rings, shaft seals, gaskets and filters) must always be renewed.

- All O-rings, rectangular-section rings, and other sealing rings must always be lubricated with white petroleum jelly before installation.

- All bearings must always be in a slightly oiled condition when installed.

- For transmissions that have been used for a large number of kilometers (> 80,000 km), all lined clutch discs and steel discs must be replaced.

- After clutches/ brakes have been damaged, the converter, oil tubes, and oil cooler, must be cleaned thoroughly.

- If brake F has been damaged, or if a considerable distance has been covered (> 150,000 km), piston F must be replaced.

The following requirements should be met before the repair work is started:

- The required special tools should be available.

(The complete set of special tools is listed in Chapter 1.7) - A suitable transmission testing rig should be available.

The required testing values can be found in the Service Bulletines.

CONTENTS

- General information

- 1.1 Picture of the transmission

- 1.2 Diagram of power flow

- 1.3 (Previously used for the oil supply diagrams, not currently used)

- 1.4 Making adjustments

- 1.4.0 Measuring the disc sets (procedure)

- 1.4.1 Adjusting clearance of brake F (snap ring)

- 1.4.2 Adjusting clearance of brake D (snap ring)

- 1.4.3 Adjusting clearance of brake E (snap ring)

- 1.4.4 Adjusting clearance of clutch C (snap ring)

- 1.4.5 Adjusting clearance of clutch A (snap ring)

- 1.4.6 Adjusting clearance of clutch B (snap ring)

- 1.4.7 Output play (shim)

- 1.4.8 Input play (shim)

- 1.4.9 Adjusting switch (detent spring)

- 1.5 Tightening torques

- 1.6 Transmission test (test bench/vehicle)

- 1.7 Special tools

- 1.8 Function tests

- 1.8.1 Position switch

- 2. Disassembly

- 2.1 Disassembly of the transmission as of the assembly group

- 2.2 Brake F with freewheel, 1st gear

- 2.3 Output

- 2.4 Tower I

- 2.4.1 Brake D, E and clutch C

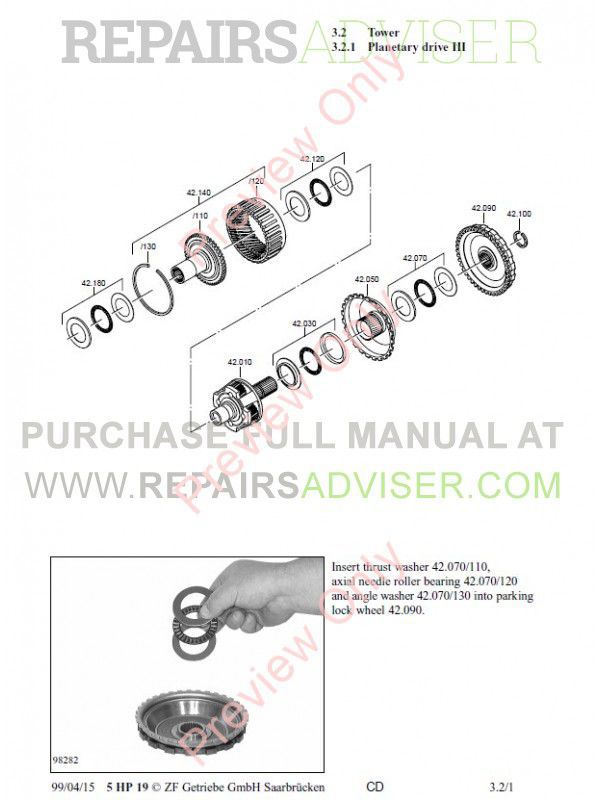

- 2.4.2 Planetary drive (III, II and I)

- 2.5 Tower II

- 2.6 Oil supply

- 2.7 Transmission with flow control valve and breather

- 2.8 Transmission with selector mechanism and parking lock

- 3. Assembly

- 3.1 Transmission with selector mechanism and parking lock

- 3.2 Brake F with freewheel, 1st gear

- 3.3 Tower I

- 3.3.1 Planetary drive (III, II and I)

- 3.3.2 Brake (E and D)

- 3.3.3 Assembly, clutch C

- 3.4 Output

- 3.5 Tower II (input with clutches A and B)

- 3.5.1 Clutch A (input)

- 3.5.2 Clutch B (input)

- 3.6 Oil supply

- 3.7 Control unit, oil pan and converter

(Complete control unit, see parts list, technical cover sheet, position Y02)

Language: English

Format: PDF

Pages: 130

BMW & Jaguar Transmission ZF 5HP24 Repair Manual PDF free online

Zf 5hp24 Parts

This manual covers the procedure for repairing the complete transmission.

The repairing of this transmission is only allowed to persons with an specific training from ZF Getriebe GmbH.

The entire disassembly and assembly procedure is described in chronological order.

The photographs were kept general in nature so that they can be used with various applications; they are not binding in every case.

CONTENTS

5hp24 Transmission Tech Manual

- General information

- Picture of the transmission Diagram of power flow

- (Previously used for the oil supply diagrams, not currently used) Making adjustments

- Measuring the disc sets (procedure)

- Adjusting clearance of brake F (snap ring)

- Adjusting clearance of brake D (snap ring)

- Adjusting clearance of brake E (snap ring)

- Adjusting clearance of clutch C (snap ring)

- Adjusting clearance of clutch A (snap ring)

- Adjusting clearance of clutch B (snap ring)

- Output play (shim)

- Input play (shim)

- Adjusting switch (detent spring)

- Tightening torques

- Transmission test (test bench/vehicle)

- Special tools

- Function tests

- Position switch

- Disassembly

- Disassembly of the transmission as of the assembly group

- Brake F with freewheel. 1st gear

- Output

- Tower I

- Brake D. E and clutch C

- Planetary drive (III, II and I)

- Tower II

- Oil supply

- Transmission with flow control valve and breather

- Transmission with selector mechanism and parking lock

- Assembly

- Transmission with selector mechanism and parking lock

- Brake F with freewheel. 1st gear

- Tower I

- Planetary drive (IE, E and I)

- Brake (E and D)

- Assembly, clutch C Output

- Tower E (input with clutches A and B)

- Clutch A (input)

- Clutch B (input)

- Oil supply

- Control unit, oil pan and converter

5hp24 Problems

Language: English

Format: PDF

Pages: 130